Why it matters

Why it matters

MaximisingUntappedPotential

Vast quantities of iron ore tailings lie dormant, representing a significant untapped resource. Harnessing this potential is crucial for driving operational efficiency and sustainable mining practices.

Our MMU and FlexSeries, coupled with the MT Lyons Unit, provide a mobile, scalable solution for efficient mineral recovery from tailings, leveraging advanced technology for profitable and sustainable operations.

The Challenge

The Challenge

Chasing yourtailings

Reprocessing tailings with traditional methods is often uneconomical and environmentally taxing. Expansive tailings dams pose catastrophic risks, while truck-and-shovel operations are carbon-intensive and labor-intensive.

Mineral Technologies’ MMU and FlexSeries Modular Plant, enhanced with the MT Lyons Unit for consistent feed, enable efficient on-site extraction and processing from tailings, optimising resource recovery while minimising environmental impact.

Investing in this technology enhances profitability by converting waste to revenue, reducing disposal costs, and featuring rapid setup and versatility for various sites, ensuring a quick ROI.

Our Solution - MT MMU

Our Solution - MT MMU

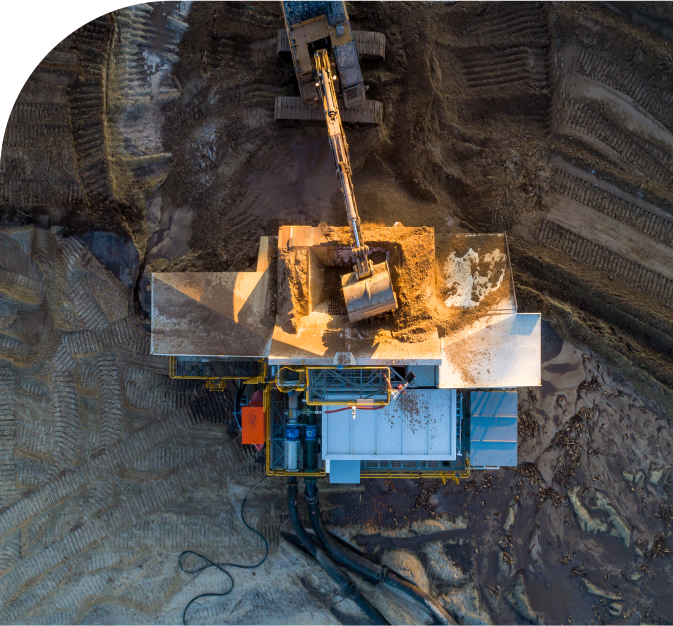

ReplaceTruck andShovel

Our Mobile Mining Unit (MMU) represents the pinnacle of soft rock mining & tailing recovery. Designed for sites where traditional methods are impractical, the MMU offers a sustainable and cost-effective solution.

Our Solution - MT Lyons Unit

Our Solution - MT Lyons Unit

ForConsistentFeed

The MT Lyons Unit (LFCU) stabilises slurry discharge in tailings dam reclamation, managing fluctuating inputs and enabling high-density pumping. This ensures consistent material flow for improved tailings management and more efficient reclamation processes.

Our Solution - MT Flex Series

Our Solution - MT Flex Series

EfficientOn-siteExtraction

The MT FLEX SERIES offers modular, customisable processing plants for tailings dam reclamation. It combines advanced spiral technology, reduced water use, and easy assembly, while minimising environmental impact and supporting efficient site restoration.

The Advantages

The Advantages

Less is more

Recover up to 70% more minerals from tailings stockpiles compared to traditional processing methods. Our advanced separation technologies ensure maximum resource recovery.

Our integrated systems feature a modular design that streamlines processes. These systems are also highly resource and energy efficient ensuring significant cost savings across the value chain.

Minimise land use, water consumption, and carbon emissions by eliminating the need for expansive tailings dams and reducing reliance on heavy machinery. Promote sustainable mining practices.

This integrated system offers adaptable configurations to suit various mining environments, ensuring optimal performance and cost-effectiveness across different operational scales. It allows for seamless deployment across multiple sites, adapting to your evolving operational needs with ease.

What thenumbers say

56.2 Billion cubic meters

Of tailings stored in tailings dams globally.

50% Reduction in costs

Mineral Technologies’ MMU can reduce operating costs by up to 50% compared to truck-and-shovel operations.

$1.2 Billion in extraction costs

Estimated global extraction costs by the mineral sands industry alone.

70% More minerals recovered

The MMU technology can recover up to 70% more minerals from tailings compared to traditional processing methods.

Finally we found a solution which makes economical sense to reclaim the remaining grade from our dams.

What is Next

What is Next

Zero harmharmony

Prioritise environmental responsibility while driving profitability. Our innovative tailings processing solutions harmonise resource extraction with sustainable practices, securing a resilient future for mining operations and local communities. By minimising land use, water consumption, carbon emissions, and waste volumes, we enable mining activities to align with global sustainability goals while unlocking new revenue streams from previously discarded tailings. This synergistic approach not only mitigates environmental risks but also enhances operational efficiency, driving profitability and long-term viability. Through responsible resource stewardship, we empower the mining industry to contribute positively to local ecosystems, safeguard community well-being, and ensure the industry’s social license to operate, paving the way for a resilient and sustainable future.

Leopoldo Bigarella

Regional Manager – South America @ Mineral Technologies

The Expert

The Expert

ReachOut!

We’re here to help. Reach out to us today to learn more about how we can tailor our solutions to meet your specific needs and objectives. Get in touch